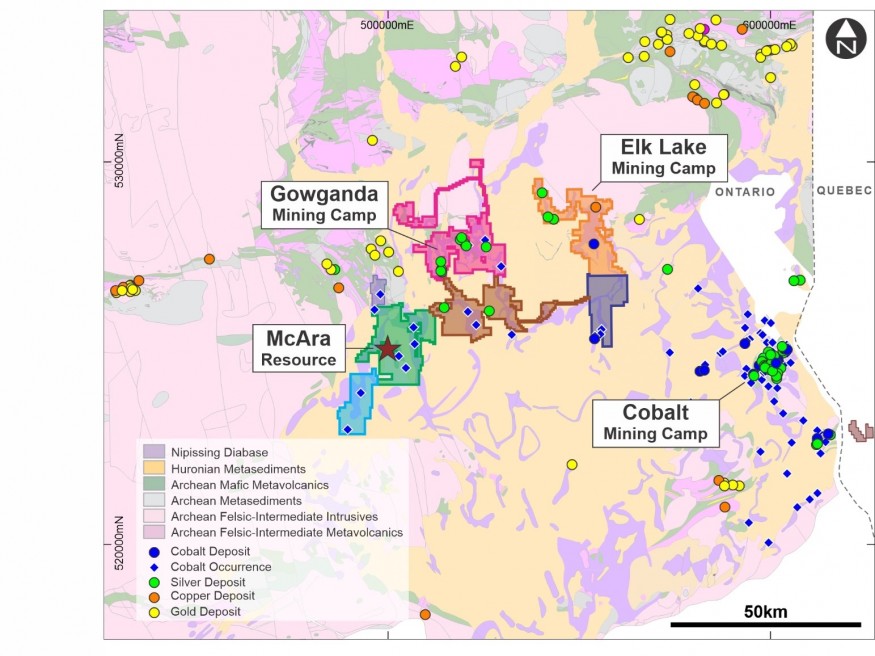

The McAra Cobalt mineral resource is located 150 km northeast of Sudbury, Ontario and is the first new cobalt dominant mineral resource delineated in the region in the past 50 years.

Cut-off grades are based on a price of US$16 per lb of cobalt, US$17 per oz silver, and assumed recoveries of 100% for underground resources.

The one-million-plus pound cobalt mineral resource outlined by BMR drilling is part of a regionally extensive and highly prospective land package of nearly 120,000 hectares, that may host additional high-grade deposits as our ongoing exploration program progresses.

Conceptually, the Company is looking to delineate a number of resources as a “hub & spoke” type development around a centralized processing plant at Gowganda or Elk Lake.

BMR provided a drillhole database to SRK as Excel format files on August 27, 2019, following a site visit by Dr.

For the BMR drillholes all final collar locations were surveyed with a Trimble differential GPS instrument using UTM coordinates and BMR completed downhole surveys at intervals of 30 metres using the Easy Gyro system.

It was found that holes drilled by BMR through the prospect had excellent spatial coverage through the area of interest, and that there was no evidence of bias introduced by including the historic holes in the estimate.

Based on SRK’s review of the available data and site visit completed in August 2019, SRK believes that the drilling, logging, core handling, storage, and analytical quality control protocols used by BMR meet industry best practices outlined in CIM Exploration Best Practices .

SRK analyzed the analytical quality control data produced by BMR for 2017 to 2019 drilling programs for the McAra deposit.

The custom-made OREAS high-grade cobalt standard exhibited a failure rate of 89% and a consistent low bias throughout the entirety of its use and should be further investigated and potentially replaced.

Samples grading over 100 ppm cobalt typically exhibited slightly higher grades in the original samples when compared to duplicate samples, suggesting a possible selective bias at the core sampling stage.

BMR has implemented formal analytical quality control monitoring for all of its field sampling and drilling programs by inserting blanks and certified reference materials into every sample sequence dispatched.

The samples were crushed to 70% < -2 mm and a riffle split of 250 grams was then pulverized to 85% of the material achieving a size of <75 microns.

The blank is inserted at the beginning, internationally certified standards are inserted at random intervals, and duplicates are analysed at the end of the batch.

Information about data verification procedures used to support scientific and technical information on the Company’s Canadian properties presented herein, as well as with respect to the results of, processing and interpretation of exploration data.

Battery is the largest mineral claim holder in the historic Gowganda Cobalt-Silver Camp, Canada, with various high-grade primary cobalt silver-nickel-copper targets located in the Cobalt Belt of Ontario and Quebec.

Such factors include, without limitation, the ability of the Company to obtain sufficient financing to complete the Punitaqui Acquisition, obtaining all required regulatory approvals necessary to complete the Punitaqui Acquisition and the acquisition of Xiana Indebtedness, risks related to share price and market conditions, the inherent risks involved in the mining, exploration and development of mineral properties, government regulation and fluctuating metal prices.